QR Code

Products

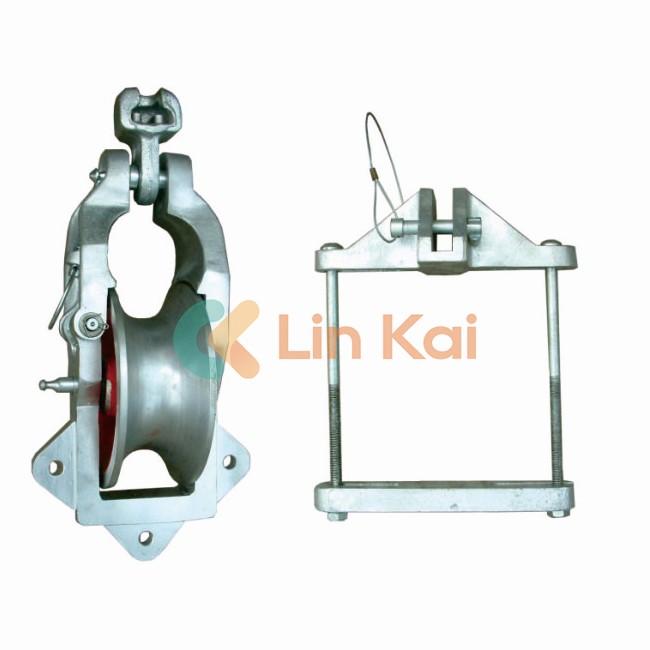

- Conductor Pulley Stringing Blocks

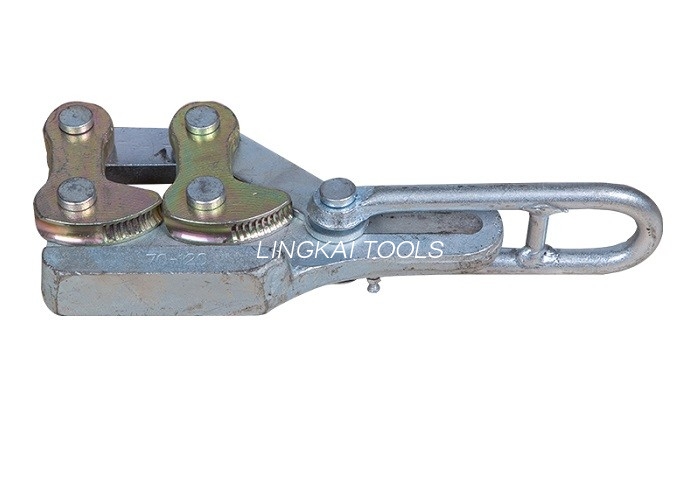

- Transmission Line Stringing Tools

- Overhead Line Stringing Equipment

- Anti-Twisting Steel Wire Rope

- Transmission Line Pulling Winches

- Tower Erection Tools Gin Pole

- Underground cable Installation Tools

- Hydraulic Tools

- Electrical Cable Pulling Tools

- Conductor Stringing Blocks

- Transmission Stringing Blocks

Contact Us

Fax

+86-57465938668

E-mail

Address

No 6, 1st Rd Xiangshan Industrial Area Ningbo, Zhejiang Province, China