Ningbo Lingkai Overhead Line Transmission Tools Manufacture has more than 20 years, engaged in the Conductor Pulley Stringing Blocks supplier, and it is only one of the top terminal plants, well known in China. We supply Conductor Pulley Stringing Blocks not only to the domestic famous big plants, but also to the more than 50 overseas countries in the overhead line transmission projects.

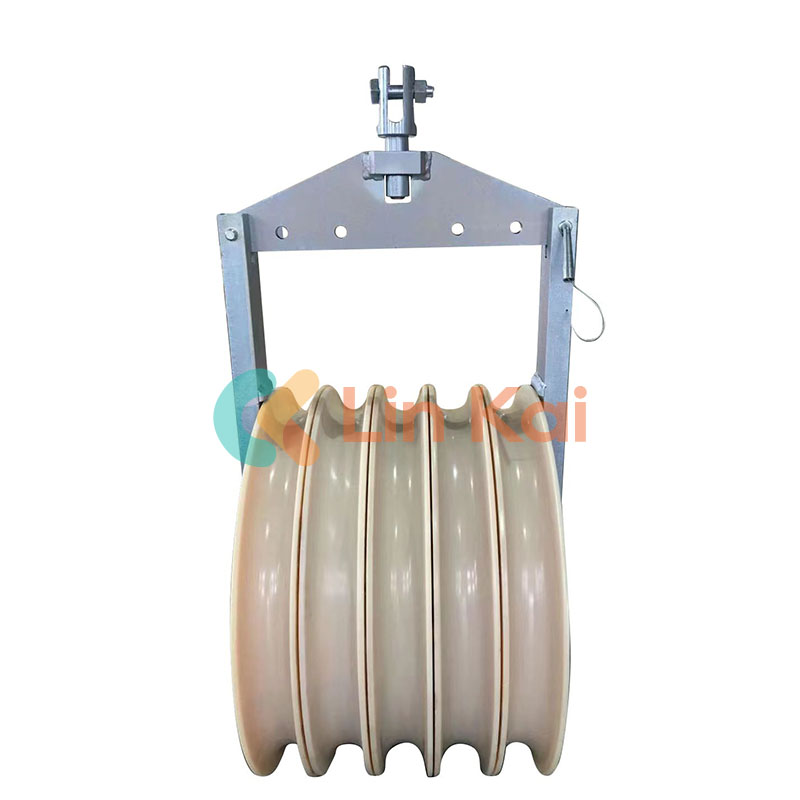

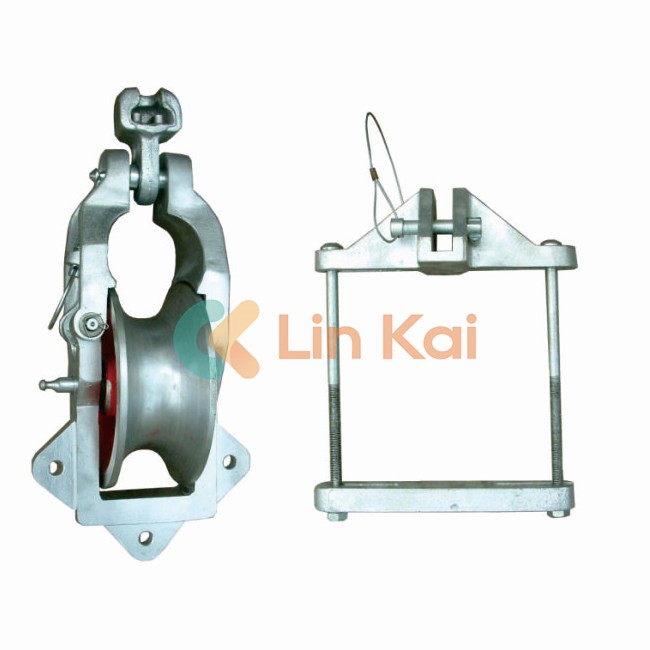

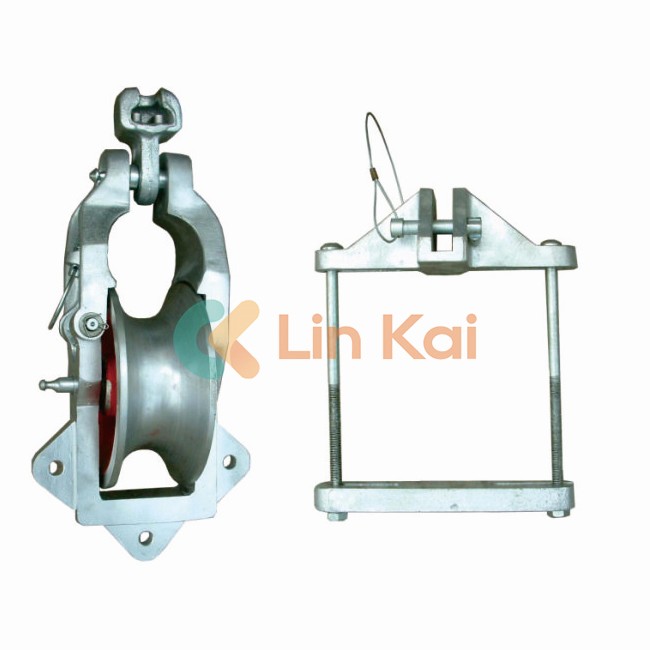

The wholesale Conductor Pulley Stringing Blocks made in Lingkai has 660,750,822,916… also to satisfied clients best, we recently developed the tandem Sheave Stringing Blocks, and more types of the Helicopter Conductor Stringing Blocks and the Grounding Roller Stringing Blocks. These head of three types of connections available: fixed (B), swivel-type (C), and hook with safety lock (D), also we has already customized more than 10 types of head for clients.

The high quality Conductor Pulley Stringing Blocks can be MC nylon, steel, and aluminum alloy material. What MC nylon, it is we imported from USA, the pure is more than 96% strength, than in China, while the frame steel is highly galvanized steel 8#, not the commonly 6#, wheels amounted on the bearings, which also the top one bearings suppliers we stably work with more than 10 years. So we only focus on the best quality best price and best service to all of worldwide clients, famous this filed in Germany, in Italy also find us to supplier the Conductor Pulley Stringing Blocks.

Conductor Pulley Stringing Blocks are indispensable tools specifically engineered for the efficient installation of overhead power lines, playing a crucial role in the electrical infrastructure development. These robust and durable blocks are meticulously designed to facilitate the smooth and safe passage of conductors during stringing operations, significantly minimizing friction and wear that can lead to costly delays and potential damage.

Constructed from high-quality materials, these stringing blocks boast a lightweight yet sturdy design, which not only enhances their portability but also ensures they can withstand the rigors of demanding job sites. The thoughtful engineering behind these pulleys includes the incorporation of precision bearings, which are essential for ensuring optimal performance. This feature reduces the risk of damage to the conductors, thereby enhancing the overall productivity and safety of the installation process.

Moreover, Conductor Pulley Stringing Blocks come in a variety of sizes and configurations, making them versatile enough to accommodate different conductor types and installation scenarios. This adaptability is vital for electrical contractors who may encounter a range of projects, from new installations to the maintenance of existing lines. The ability to select the appropriate block for specific tasks ensures that each job can be executed with precision and efficiency.

In addition to their functional benefits, these stringing blocks are designed with user convenience in mind. Their lightweight nature allows for easy handling and transportation, reducing the physical strain on workers and enabling quicker setup times. This efficiency is particularly important in the fast-paced environment of electrical contracting, where time is often of the essence.

Whether you are embarking on a new installation project or performing maintenance on existing overhead lines, Conductor Pulley Stringing Blocks provide the reliability and efficiency needed to get the job done right. Their robust construction, combined with advanced engineering features, makes them a vital addition to any electrical contractor's toolkit, ensuring that every stringing operation is executed smoothly and effectively. With these essential tools at your disposal, you can enhance your workflow, improve safety standards, and ultimately deliver high-quality results to your clients.