Ningbo Lingkai Overhead Line Stringing Equipment supplier, we has the come along clamp, tighten tools hoist lever block and the reel stands three classy. They are widely used in the overhead line transmission construction site. They are under testing 1.5 and 3 times of the rated load before shipping out, while we adopt the new technology and customized parameters in them.

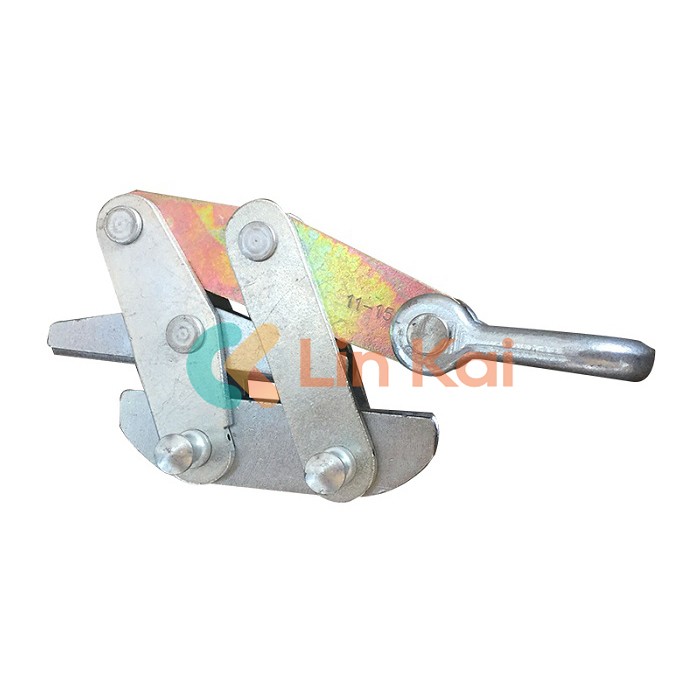

The high quality Overhead Line Stringing Equipment, come along clamps, grippers, they are for earth wire, anti-twisting steel wire, conductor and opgw and etc. they made of the alloy steel and the Aluminum magnesium alloy compact, and new skill in the jaw processed, and with hook, all and all small points developed and focus on, it is aim to make the highly strength of these grippers, and long life time, and top safety for operators in site.

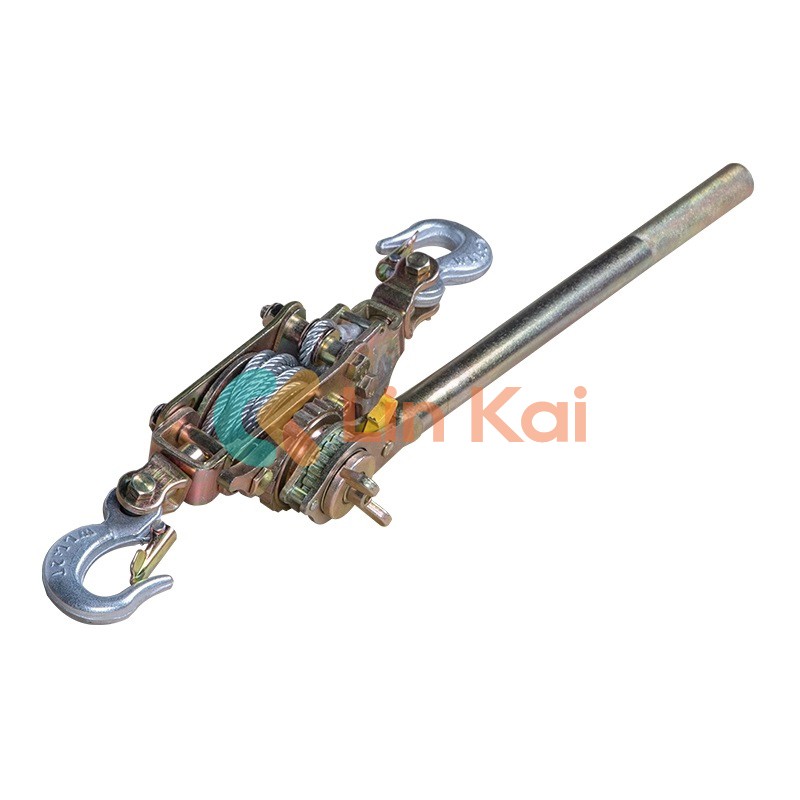

Our fashion chain tackle block, tackle lever and the HSS tirfor hand winch pulling tools are very welcomed, play a very important role in the Overhead Line Stringing site.

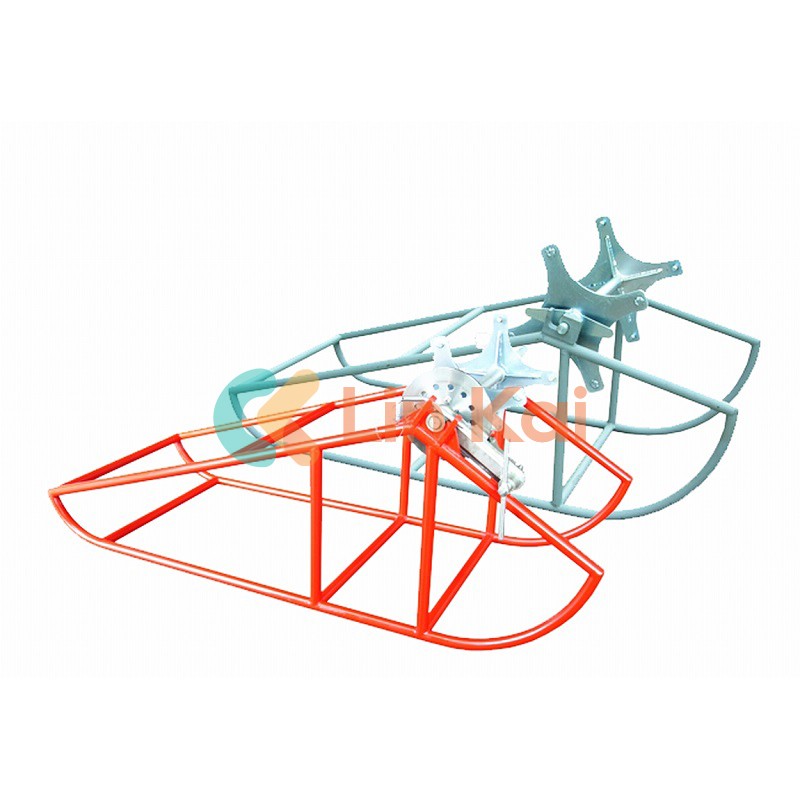

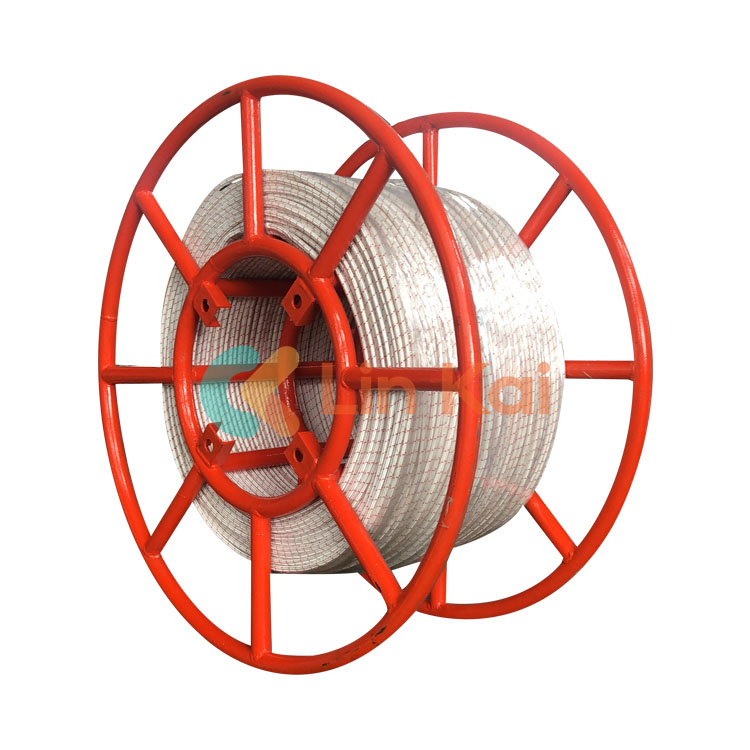

We manufacture different tons and models reel stands with brakes for the overhead stringing lines and conductors.

Overhead line stringing equipment plays a crucial role in the operations of utility companies and contractors engaged in the installation and maintenance of overhead power lines. This specialized equipment is meticulously engineered to facilitate the efficient and safe stringing of conductors over extensive distances, thereby ensuring that the installation process is not only streamlined but also highly effective.

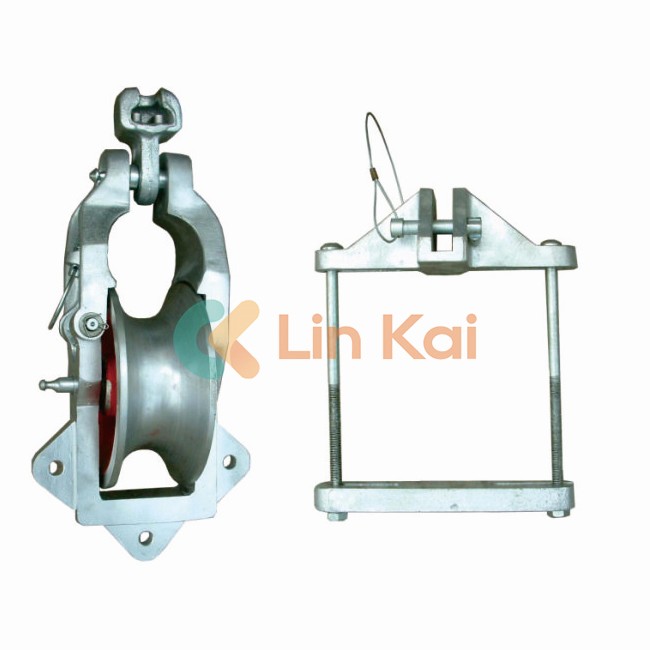

The equipment is characterized by its robust construction and advanced engineering, which are essential for handling the demanding tasks associated with overhead line work. Typically, it comprises a variety of components, including stringing blocks, tensioners, and pullers. Each of these elements is designed to work in harmony, effectively managing the weight and tension of the cables being installed. Stringing blocks, for instance, are used to guide the conductors around corners and obstacles, while tensioners help maintain the appropriate tension in the cables to prevent sagging or excessive strain. Pullers are employed to draw the conductors into place, ensuring a smooth and controlled installation process.

One of the standout features of overhead line stringing equipment is its ability to withstand harsh environmental conditions. This durability makes it reliable for use across various terrains and climates, from rugged mountainous regions to flat plains and urban environments. The equipment is often constructed from high-quality materials that resist wear and tear, corrosion, and other forms of damage, ensuring longevity and consistent performance even in challenging situations.

In addition to its robust design, overhead line stringing equipment is also engineered with user-friendly features and safety mechanisms. These enhancements not only boost productivity but also significantly reduce the risk of accidents during the installation process. Safety features may include automatic shut-off systems, overload protection, and ergonomic designs that minimize the physical strain on operators. By prioritizing safety, this equipment helps ensure that projects are completed efficiently, on schedule, and within budget.

Whether the task at hand involves new installations of power lines or upgrades to existing infrastructure, overhead line stringing equipment is an indispensable asset for any electrical infrastructure project. Its ability to streamline operations, enhance safety, and improve overall efficiency makes it a vital tool for utility companies and contractors alike. As the demand for reliable and efficient power distribution continues to grow, the importance of high-quality overhead line stringing equipment will only increase, solidifying its role as a cornerstone of modern electrical infrastructure development.