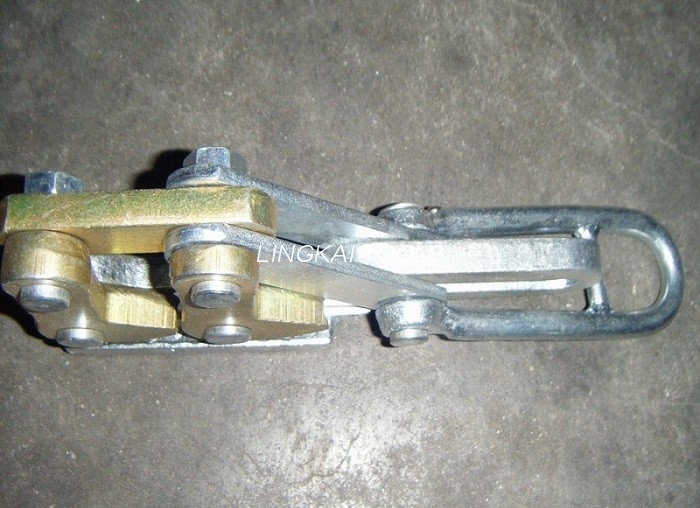

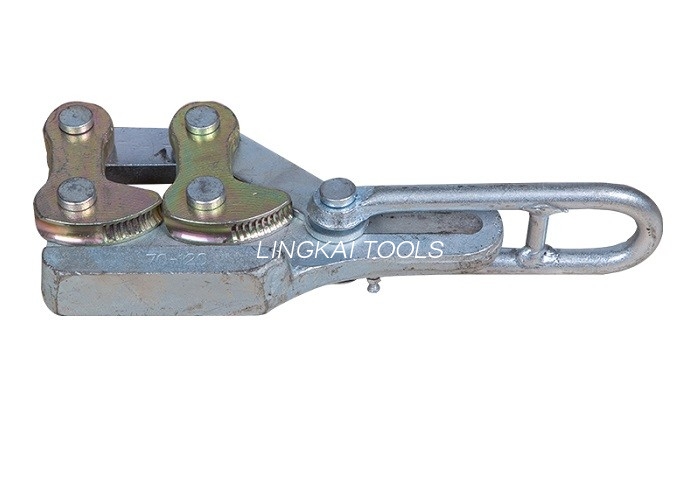

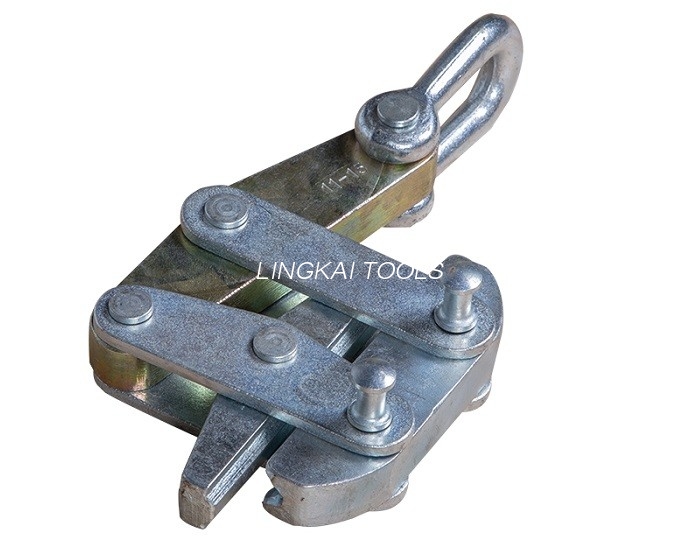

As a professional high quality Come Along Clamp manufacturer from Lingkai, China. Mainly including 48Mm Self Gripping Aluminum Alloy Conductor Gripper, Insulated Conductor Transmission Line Stringing Tools Cable Pulling Clamps, 80kN Max Load ACSR Conductor Self Gripping Clamps, etc.

What is a come along clamp used for?

Come Along Clamp is mainly used to move with the workpiece on the automated production line to complete the conversion processing of each station. This fixture is particularly suitable for workpieces with irregular shapes that are not easy to automatically position, clamp and transport. Through the Come Along Clamp, the workpiece can be automatically transported and transferred between the stations to ensure the relative position of the workpiece and the tool, thereby improving the processing accuracy and production efficiency. In addition, the design of the Come Along Clamp needs to be carried out according to the shape and process requirements of the workpiece, which belongs to the scope of special fixtures, and its workpiece clamping part needs to be specially designed to meet specific processing requirements.

The main application scenarios of the Come Along Clamp include:

Automatic production line: On the automatic production line, the Come Along Clamp moves with the workpiece to complete the conversion processing of each station. It is suitable for complex contour workpieces with irregular shapes and no good conveying base surface.

Machining center and flexible manufacturing system: In these automated production environments, the traveling fixture is used to clamp the workpiece, ensure processing accuracy, and improve production efficiency.

The design and use of the traveling fixture can reduce the labor intensity of workers and expand the processing range of machine tools. Through flexible and changeable design, it is particularly suitable for trial production of new products and single-piece small batch production. In addition, the bottom plane of the traveling fixture is generally separated into a positioning base surface and a transportation base surface to protect the accuracy of the positioning base surface and ensure high-precision processing requirement.